Do Metal Pools Rust? Best Anti-Corrosion Treatments for Steel & Aluminum Pools [2025 Guide]

Metal pools are strong and durable, especially if made of steel or aluminum. But many pool owners ask themselves: Do metal pools rust? The answer is yes—metal pools are prone to rust over time due to exposure to water, pool chemicals, and environmental factors such as humidity and salt. Rust not only affects the appearance of your pool but can also compromise its structure if left untreated.

Rust is avoidable with proper care and maintenance. Anti-corrosion methods, including protective coatings, sacrificial anodes, and routine water chemistry balancing, can significantly increase the longevity of your metal pool. While steel and aluminum pools have unique properties, both can effectively resist corrosion with proactive measures.

Let’s examine the causes of rusty metal pools and the best solutions for keeping them in top shape for years.

Why Do Metal Pools Rust?

Why do metal pools rust? Here are the research-backed causes of rust in steel and aluminum pools. Although metal pools are quite durable, they are not immune to corrosion. Rust is the reaction of metals with water, oxygen, and chemicals and can result in structural damage.

The first step to prevention is understanding the causes.

Chemical Exposure & Pool Water Chemistry

Chemical exposure is a significant contributing factor to rust in metal pools. Common components of pool chemicals, such as chlorine and salt, can speed up corrosion by penetrating protective layers on metal surfaces. Saltwater pools eat up aluminum and steel components. Moreover, pH imbalance is also a major concern.

Acidic water with low pH levels is more effective at corroding metals. Maintaining the pH between 7.2 and 7.8 is essential for rust prevention. Total alkalinity also matters, as it keeps the pH in check; faulty alkalinity can lead to irregular pH, which makes it more likely rust will form on pool walls, ladders, and other metal parts.

Environmental Reasons

Environmental conditions tend to play a significant role if metal pools are rusting. In high-humidity environments like indoors and coastal regions, moisture is trapped on metal when it is exposed, leading to faster oxidation and rusting. Salt air deposits corrosive chlorides on exposed metal parts, so pools in coastal regions are at a greater risk.

A humid and slightly corrosive environment exists under some conditions due to airborne pollutants such as sulfates and chloramines that condense on metal surfaces, resulting in corrosion — even for stainless steel. Having the right knowledge for these facts will help property owners reduce the likelihood of rust in their metallic pools by addressing these chemical and environmental factors. Maintenance and monitoring also play a key role in keeping corrosion at bay.

Best Anti-Corrosion Treatments for Steel & Aluminum Pools

Rust-proof treatments for metal pools and some modern solutions can greatly increase the life of steel and aluminum pools. These methods include barriers, sacrificial anodes, and cathodic protection to protect pool parts from corrosion.

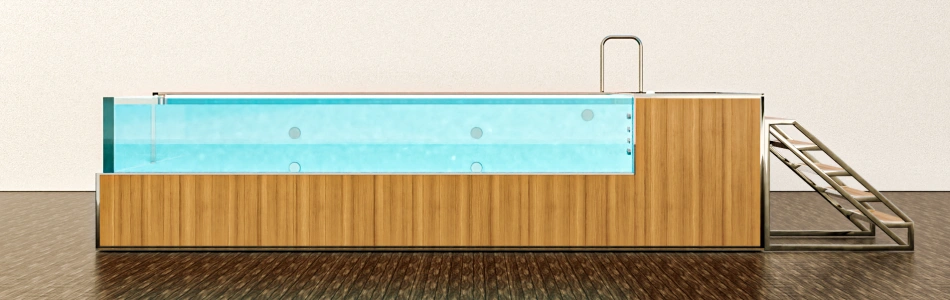

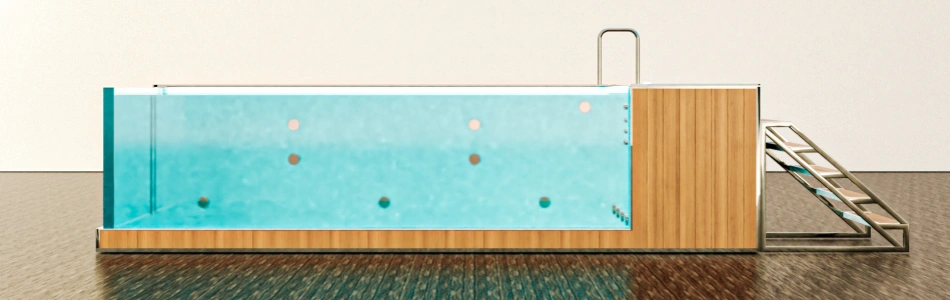

Epoxy & PVC Liners

Epoxy coatings and PVC liners can be beneficial for rust prevention. Epoxy is a paint-like, robust coating that protects metal surfaces from exposure to water. It is simple to put on and can last a few years, depending on how frequently the pool is used and how well-maintained the chemicals are. On the contrary, PVC liners contain high-resistance polyester covered with fused PVC sheets.

Because of their waterproofing and chemical resistance properties, they are suitable for use in steel and aluminum pools. These materials must be applied according to specific techniques to ensure proper adherence to the pool panels and their ability to hold up long-term.

Sacrificial Anodes

Sacrificial anodes are metal rods that corrode before the pool’s structural components do. The resistivity level also depends on the type of cathodic protection used; Zinc and magnesium anodes have a lower resistivity level, so they are generally used in seawater. These anodes are installed close to sensitive equipment, such as filters or heaters, and are connected to the bonding system for most pools. Replacing your sacrificial anode every 6–12 months will protect your vessel from corrosion by electrolysis.

Cathodic Protection Systems

Cathodic protection systems prevent rust using electrical principles. Bonding ties all metal parts to a common ground, which helps mitigate galvanic corrosion by equalizing the electrostatic electric potential. Grounding also enhances safety by helping divert stray currents from pool equipment. When used in conjunction with sacrificial anodes, cathodic protection systems provide complete corrosion protection in heavily chlorinated or saltwater pools.

Preventing Galvanic Corrosion in Metal Pool Systems

In a pool system, galvanic corrosion can happen when two different metals come into contact with water and the salts and chemicals present, leading one metal to corrode faster. For example, learning how to prevent galvanic corrosion between metals in a pool might require isolating materials and adhering to safety measures to safeguard steel and aluminum components.

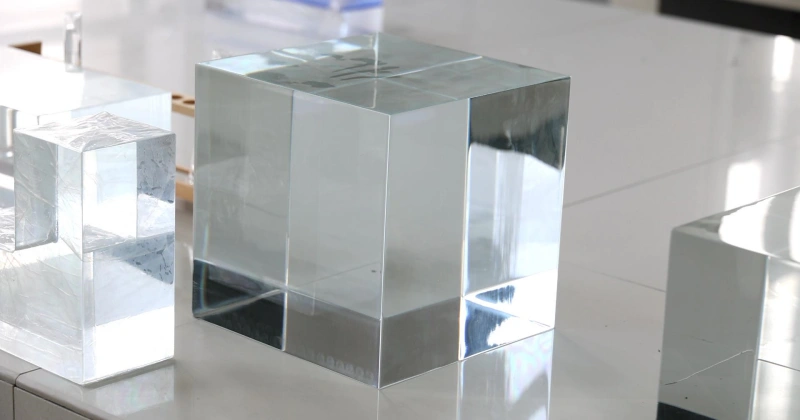

Insulating Dissimilar Metals

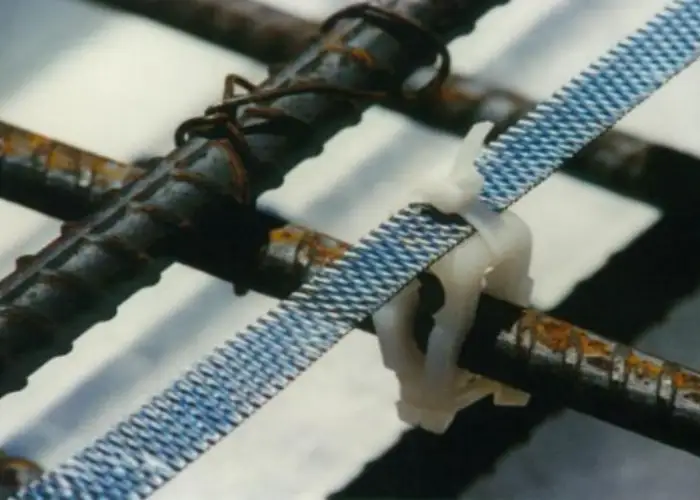

Plastic or rubber gaskets fill the gap between one metal (like steel bolts) and another (like aluminum joints), preventing the corrosive effects of their contact. Another way to isolate metal parts through the use of non-conductive sleeves or coatings is in pumps, ladders, and railings. For instance, nylon washers in bolt connections or PVC-lined fittings prevent electrical currents from passing between dissimilar metals, slowing the formation of rust.

Pool Bonding Best Practices

Bonding ensures all metal components (ladders, pumps, panels) in a pool are directly connected to a grounding system, equalizing electrical charge and minimizing corrosion risk. The NEC code (Article 680.26) stipulates bonding wires to connect metallic parts within 5 feet of the pool to a copper grid buried around the perimeter. This guides stray currents or leaks safely to the ground rather than to metal surfaces, causing corrosion. Improper installation can increase corrosion and safety hazards, so always have a licensed electrician design and test the bonding system.

Maintenance Checklist to Prevent Pool Rust

Routine maintenance is key to keeping your metal pool in good condition and preventing rust. Even basic things like cleaning the pool metal and balancing the pH can prevent steel and aluminum parts from corroding. Regular maintenance allows your pool to stay safe, long-lasting, and aesthetically pleasing.

Weekly upkeep includes checking the pool’s pH levels to make sure they remain between 7.2 and 7.8. Balanced pH stops corrosion of metal surfaces by preventing water from getting too acidic or too alkaline. Ladders, panels, and other exposed metal parts must also be scrubbed of salt deposits. Taking these depositions maintains less potential for chloride-induced corrosion.

Inspections should be conducted monthly and should focus on sacrificial anodes and liners. Inspect anodes for wear; if they are heavily corroded, replace them to ensure continued protection for the pool’s metal components. Check PVC liners or epoxy coatings for cracking or deterioration that may expose underlying metal substrates to water and chemicals.

Get a professional corrosion audit every year to uncover all the hidden problems. Technicians can test bonding systems, examine structural integrity, and recommend repairs or upgrades to keep rust from spreading. This approach can save you from expensive damage and keep your pool in great shape for years.

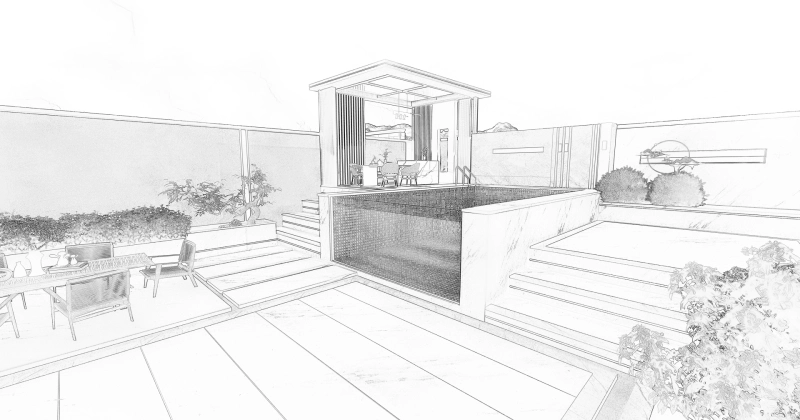

Choosing Corrosion-Resistant Pool Materials

The selection of materials is crucial for making the pool rust-resistant and long-lasting. Stainless steel and powder-coated aluminum are considered the best metals for saltwater pools as they are durable and corrosion-resistant.

Stainless Steel Grades Comparison

Both 304 and 316L stainless steels are popular choices for pool construction but perform best under certain environmental conditions. 304 grade is the most cost-effective and is acceptable for indoor pools or areas with lower chlorine levels. However, it is not as resistant to chlorides and can corrode in saltwater or humid environments. 316L stainless steel, often called marine-grade stainless steel, contains molybdenum , making it better suited for saltwater and chlorinated environments. This makes it suitable for coastal locations or high-salinity pools. 316L is pricier than 304L, but given its durability in cold or hot environments, the premium is worth it.

Powder-Coated Aluminum

The other class of corrosion-resistant pools is powder-coated aluminum. The coating serves as a protective barrier that blocks oxidation and rust. It is lightweight and impact-resistant, ideal for pool panels and enclosures. Moreover, if maintained properly, this offers up to 30 years of protection. However, damaged coatings can be tricky to repair. With all its downsides, aluminum is naturally rust resistant, and powder coating gives it an added layer of protection, making it a relatively safe choice for saltwater pools.

When to Call Professionals for Pool Corrosion Issues

Although small rust spots can usually be treated with DIY solutions, recurring cases indicate that expert pool corrosion repair services are needed. When rust stains won’t come off after cleaning or treatments don’t arrest metal degradation, you need to call the professionals. Another glaring indicator is finding electrical currents within pool water — a sign that bonding or grounding systems are not working correctly and pose safety hazards.

Conclusion

Although metal pools rust in time, the treatments outlined in the article guarantee decades of use. Regular maintenance, protective coatings, and the proper bonding systems can greatly slow corrosion, prolonging your pool’s lifespan.