What Is a Glass Swimming Pool

Glass swimming pools are a pool design concept where the walls or the bottom of the pool are made of transparent glass or acrylic panels. This innovative design allows swimmers to see the surrounding scenery through the transparent walls while providing clear visibility of pool activities to onlookers. Using glass in pool design creates a transparent and modern appearance, offering swimmers a unique visual experience distinct from traditional pools.

Pool Acrylic panel VS Pool Glass wall

Typically, for safety reasons, real glass is not used in constructing glass pools; instead, acrylic panels, also known as plexiglass panels, are employed.

- · Transparency and Clarity: Acrylic window panels boast exceptional clarity, allowing up to 92% of visible light to pass through, more than glass. This high transparency rate ensures that spaces feel more open and connected to the outdoor environment, enhancing the aesthetic appeal of any structure.

- · Seamless Integration: With the ability to be molded and shaped into various forms, acrylic panels can be customized to fit any design, providing a sleek, modern look that seamlessly integrates with both interior and exterior spaces.

- · Light Manipulation: The unique properties of acrylic allow it to manipulate light in creative ways, adding depth and dimension to spaces. Whether diffusing natural light to create a soft glow or enhancing the vibrancy of colors through its clear surface, acrylic panels elevate the visual experience.

- · Impact Resistance: Acrylic panels are significantly more impact-resistant than traditional glass, making them a safer alternative for areas prone to accidents or environmental stressors. This feature is especially beneficial in public spaces, where safety is a paramount concern.

- · Shatterproof: Unlike glass, which can shatter into sharp pieces, acrylic panels fracture into larger, duller pieces if broken, reducing the risk of injury. This characteristic makes acrylic panels an ideal choice for swimming pools, balconies, and other areas where glass breakage poses a significant risk.

- · Weather and UV Resistance: Acrylic is resistant to weathering and ultraviolet (UV) light, ensuring that it does not yellow or become brittle over time. This durability makes it suitable for outdoor applications where exposure to the elements is a constant factor.

- · Malleability: Acrylic can be heated and molded into various shapes and sizes, allowing for custom designs that would be difficult or impossible to achieve with traditional glass. This flexibility opens up a world of design possibilities, from curved aquarium walls to intricate architectural features.

- · Bonding and Fabrication: Acrylic panels can be easily bonded together with solvents and adhesives, creating seamless joints that enhance the material's aesthetic appeal. This property is particularly useful in creating large, continuous surfaces without visible seams or joints.

- · Lightweight: Acrylic is lighter than glass, making it easier to handle and install, especially in large panels or complex shapes. This can significantly reduce the structural support requirements, allowing for more innovative and ambitious designs.

Comparing the Pros and Cons of Acrylic Glass and

Traditional Swimming

Pools

People are often captivated by the breathtaking visual impact and design of acrylic glass swimming pools, making it challenging to decide between them and traditional concrete or fiberglass pools when constructing one. While acrylic glass pools undeniably offer numerous advantages compared to conventional pools, it's crucial to acknowledge that they also have their fair share of drawbacks. Below, I'll outline the pros and cons of each option to help you make a decision that aligns with your preferences.

Advantages

One of the main reasons people opt for acrylic glass swimming pools is the stunning visual impact they offer. The transparent walls create a mesmerizing effect, enhancing the structure's aesthetic appeal and fostering a sense of openness and connection with the surroundings. The transparent look and the ability to see through the pool walls create a visually captivating aquatic scene. It's like opening a window to the underwater world, providing a fascinating view of the water, wildlife, and swimmers. For upscale residences, hotels, and resorts, acrylic pools are a striking showcase.

Safety is paramount in any swimming pool design. Acrylic glass is well-known for its durability and strength. While it may not be as hard as concrete, it's incredibly durable and impact-resistant compared to glass pool panels. Unlike glass, acrylic won't shatter, which eliminates potential hazards. Unlike concrete, it won't crack or require frequent surface repairs. This toughness translates to a safer, longer-lasting pool with fewer maintenance demands.

One of the biggest perks of acrylic swimming pools is the level of design flexibility they offer. The flexibility of acrylic allows for innovative designs beyond the capabilities of conventional materials. Whether it's curved shapes, large seamless panels, or unique features like underwater windows, acrylic gives architects and designers the creative freedom to bring their most ambitious visions to life. This versatility, coupled with the material's aesthetic appeal, enables the creation of stunning, one-of-a-kind pools that become the centerpiece of any property.

Acrylic glass panels provide a clear view into the pool, allowing swimmers to enjoy underwater scenery. This feature is particularly enticing for commercial pools like resorts, hotels, or aquariums, and it's also appealing to homeowners seeking a unique swimming experience.

Acrylic glass transmits light into the water more effectively than traditional pool materials. This helps naturally heat the pool water using sunlight, reducing heating energy costs. The clear panels create a brighter and more inviting swimming environment, minimizing the need for additional lighting fixtures and enhancing the overall ambiance of the pool area.

Disadvantages

The major downside of acrylic pools is that they can cost a pretty penny compared to concrete or fiberglass. You’re considering shelling out two to three times more for the acrylic panels and installation than the latter options. Plus, you'll need specialized contractors for custom acrylic fabrication and installation.

The acrylic panel’s non-porous surface prevents algae growth and staining, meaning less scrubbing and fewer chemicals are needed to keep the pool looking pristine. While acrylic panels are durable, they require regular upkeep to maintain clarity and appearance. They're prone to scratching and can suffer chemical damage or scuffing if improperly maintained and handled. This means regular cleaning, polishing, and potentially refinishing, which adds to the ongoing costs.

In some areas, acrylic glass swimming pools may not be as readily available as traditional pools. Finding experienced contractors or builders familiar with acrylic glass construction might pose more of a challenge, especially in regions where this technology is rare. However, there's no need to worry because AUPOOL offers global services to help address most of your concerns regarding acrylic glass pools.

Improper installation or maintenance of acrylic glass panels can lead to issues like expansion and contraction with temperature fluctuations, potentially causing problems like warping or leaks. Ensuring proper sealing and structural support is crucial for mitigating these risks. This requires a highly professional team to tailor plans based on various environmental factors.

Overall, for luxury residences and high-end properties, the striking design of an acrylic pool may outweigh the additional costs and maintenance. While acrylic glass swimming pools offer unique advantages in aesthetics and design, prospective homeowners should carefully assess the challenges and considerations before deciding.

Different Types of Acrylic Glass Swimming Pool

Designs and Structures

Typically, we categorize acrylic glass swimming pools into three types based on installing acrylic panels and their structures and locations: acrylic glass-walled pools, acrylic glass window pools, and acrylic glass bottom pools.

The difference between "glass pool windows" and a “glass-walled pool" lies in how the acrylic panels are positioned. In a glass pool window, the acrylic panel is entirely submerged underwater, like a window opening underwater. The acrylic panel is structurally fixed all around its perimeter, unlike in a glass-walled pool where there's no structural support above the acrylic panel. This means that in glass pool windows, the acrylic panel can be thinner because it doesn't need to resist deformation, bending, or breaking under water pressure like in glass-walled pools. Glass pool windows are typically installed to offer underwater views, enhance aesthetics, or create an open atmosphere in the pool area.

Glass bottom pools are a luxurious and visually stunning feature in which a section of the pool's floor is made of transparent acrylic glass, allowing swimmers to see through to the area below. These pools are often built at elevated heights or over other structures, such as buildings or cliffsides, creating a captivating experience for those swimming above. Glass bottom pools are popular in resorts, hotels, and high-end residences, offering a unique and exhilarating swimming experience. They provide a sense of floating or swimming above the ground, with the illusion of transparency adding to the excitements.

Are You Ready?

you ready to build your dream acrylic glass pool? Explore our guide and

contact our pool experts for any questions or details.

First Step

Share your acrylic glass pool information

Blueprints

CAD drawings or floor plans would help us provide accurate suggestions

Brilliant idea

No blueprints? No worries! Share your fantastic idea with us, including the type of pool, depth, environmental considerations, and more. Please don’t fret about missing details; our pool experts will confirm each. Let's collaborate to craft the perfect pool plan together.

Let's See Your Brilliant Idea Take Shape !

Upon receiving your input, AUPOOL's engineers will draft preliminary sketches and renderings of your acrylic glass pool. These visuals will outline the dimensions of the acrylic panels, demonstrate installation techniques, and provide an initial depiction of your brilliant concept. You can trust that any new ideas you propose will be promptly integrated into the design process, ensuring we work together seamlessly to enhance and perfect your vision!

Divided Acrylic Panels

When dealing with large or complex acrylic pool engineering projects, we must divide the acrylic panels to ensure smooth production, transportation, and installation, for example, the "1 Hotel Acrylic Glass Bottom Swimming Pool" project we completed, which spans 180 feet in length and 72 feet in width. We divided the acrylic panels into 27 sections to facilitate transportation and installation and utilized seamless assembly techniques. As a result, the completed pool appears as if it's made from a single piece of acrylic, providing an unparalleled visual experience.

Installation &

Engineering Blueprints

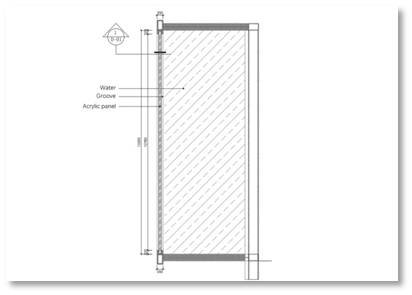

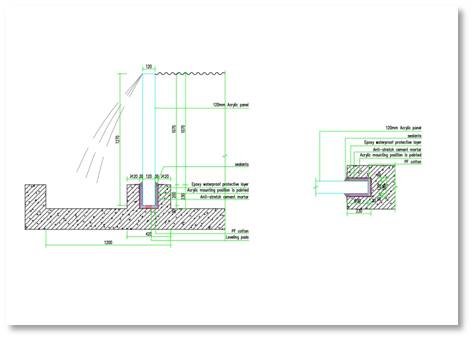

After achieving the expected preliminary results, we will move on to a crucial step: preparing detailed engineering blueprints.

Acrylic Panel

Factory & Production

Once the drawings and plans are confirmed to be accurate and after the contract is signed, we'll begin production of the acrylic panels. The production timeline is determined based on the weight of the acrylic panels. Typically, our experts will provide a timeframe before production begins, and we'll keep you updated on the progress throughout the production process.

AUPOOL, established in China in 1995, has completed over 1,000 global projects, ranging from aquariums to acrylic window panels and swimming pools. Equipped with cutting-edge production processes and a skilled installation team, AUPOOL specializes in producing extra-thick acrylic sheets. Our seamless joining technology ensures consistent strength and durability, especially in large-scale pool projects. With nearly 30 years of operation and zero accidents, AUPOOL guarantees top quality and safety.

Get Professional Service NowSafe Delivery

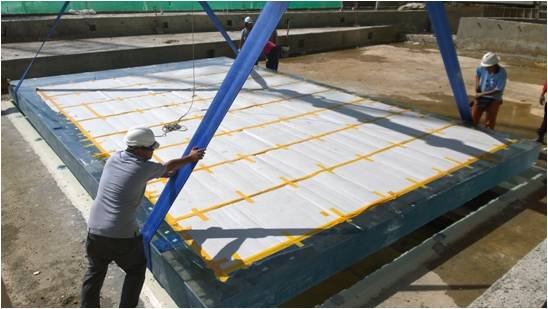

Next, we need to figure out how to safely and securely transport the acrylic panels to the site and then carefully place them onto the framework without any damage and on time. This involves confirming packaging, transportation, and hosting plans.

Acrylic Installation

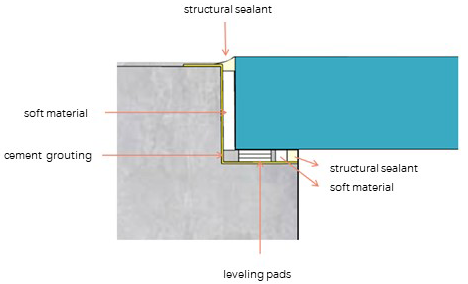

Before installing the acrylic panels, the first step is to waterproof the junction between the acrylic and the installation groove. We use alternating layers of epoxy resin and fiberglass cloth to ensure a smooth, sturdy waterproof surface that adheres well to the structure. Once the waterproof layer is dry, we can proceed with the next step.

We use a leveling tool to adjust the position of the acrylic bottom groove, laying down shims as needed to ensure the acrylic panels are level once placed in the groove.

Before placing the acrylic panels into the groove, it is essential to recheck the dimensions and shapes of both the acrylic panels and the acrylic installation groove. Compare the dimensions of the acrylic panels and the groove to ensure that the acrylic can safely fit into the groove. Only then can the acrylic be hoisted into place. This step is crucial!!!

After placing the acrylic panels into the groove, we pour non-shrinking cement to fill the gaps between the acrylic panels and the groove. Soft cotton is inserted around the edges to allow for expansion and contraction of the acrylic. Once filled, we seal the structure with sealant.

Installation Guidance: We will provide customers with instructional videos of the entire construction installation process for reference, and offer installation recommendations based on the actual situation.

About

Seamless Joining

Seamless joining is a solution for projects where using a single panel to

complete the entire project is not feasible. Typically, our single panels

can reach a maximum length of 46 feet. If the size exceeds this limit or

there are unique shapes or installation environment restrictions, we need to

divide the panels into multiple pieces for transportation and perform

seamless joining on-site at the project location.

We adjust the two acrylic panels that must be joined to the appropriate

positions to ensure the joint gap meets the set width. After changing the

gap, we simultaneously make jointing molds. The jointing mold involves

aligning the two acrylic sides to be joined, changing the width uniformly by

about 3-4mm, and sealing with unique materials. Each sealing leaves a

pouring port, and all joints are molded synchronously.

Once all acrylic panels are in place, we construct an overall thermal and

dust-proof shed in the acrylic construction area. Depending on the site's

climate, we install air conditioning or heaters inside the shed to adjust

the temperature appropriately.

When the preparation work is complete, we start pouring. First, we vacuum

the pre-prepared jointing material to prevent bubbles. After filling the

joint gap, we seal the pouring port. After the joint gap is completely

cured, we inspect it for bubbles or apparent transitions. Once confirmed, we

begin polishing until the seam is smooth. There should be no apparent

transitions or reflections on the surface.

FEATURED IN

Malaysia D'Latour Bandar Sunway,This development comes with two SoHo and serviced apartment towers which are 23-storey tall.Their fully functional layout design, combined with modern finishing is highly suitable for both work and everyday living.

Constructed using a suspended transparent acrylic pool, we've created waterfalls within the canyon, allowing the floating transparent acrylic pool to evoke an elegant and dynamic spatial experience across various dimensions.

From The

Blog

For more exciting insights into acrylic glass pool construction, check out more details

Frequently Ask Question

Aupool boasts advanced production lines and equipment, top-notch manufacturing and construction techniques, a professional structural team, and technical support from a physics institute. With a flawless safety record over nearly 30 years, we prioritize your safety above all else.

Glass swimming pools utilize transparent acrylic panels for walls or the bottom, offering a unique visual experience by allowing swimmers and onlookers clear views of the surrounding scenery.

Acrylic offers superior clarity, allowing up to 92% of visible light through, and is more impact-resistant and safer than traditional glass. Its versatility also allows for custom shapes and sizes.

Yes, acrylic panels are significantly more impact-resistant than glass and, if broken, fracture into larger, duller pieces that are less likely to cause injury.

Acrylic is highly resistant to weathering and UV light, ensuring it does not yellow or become brittle over time, making it an ideal choice for outdoor applications.

Our expert team uses state-of-the-art techniques for installation, ensuring the panels are perfectly sealed and integrated into your pool design for a leak-proof and aesthetically pleasing outcome.

Manufacturing timelines vary, with a general estimate of 45 days for sheets weighing 1-5 tons. Installation timelines depend on the project's complexity and will be detailed in your custom plan.

Acrylic panels require minimal maintenance, primarily regular cleaning to maintain their clarity. We will provide specific care instructions based on your installation.

Absolutely! One of the greatest benefits of acrylic is its malleability, allowing us to customize panels to fit any pool shape or design specification.

For a tailored project plan, please share details such as your pool's plans, location, desired features, depth requirements, and whether it will be indoor or outdoor.

With over 1,000 successful projects worldwide and a legacy of over 25 years, AUPOOL combines innovation, quality, and expertise in glass swimming pool design and installation, ensuring each project meets our high standards of excellence and safety.