Long-Term Reviews of Metal Pools in Coastal Areas with Salty Air

Nice weather around? Imagine your dream house at the edge of the sea with its swimming pool to cool down on the hottest days. However, if you are constructing a metal pool near the sea, it is not only the scenery you have to think about. Metal pools are durable and economically efficient, but the salty weather and marine climate can affect the structure in the long run.

It also raises important questions of how well metal pools can survive the long haul. Are they worth the investment, or are they only good for repairs all the time? How did the clients like the product over a longer period of use? In this article, we will discuss real-life reviews, maintenance difficulties, and how to increase the longevity of metal pools in marine settings.

Understanding Metal Pools

To better understand the difficulties that metal pools experience in coastal regions, it is necessary to discuss the various types of metal utilized in pool construction. Every type has its advantages and disadvantages, and not all metal pools respond in the same manner when exposed to salt and moisture.

Types of Metal Pools

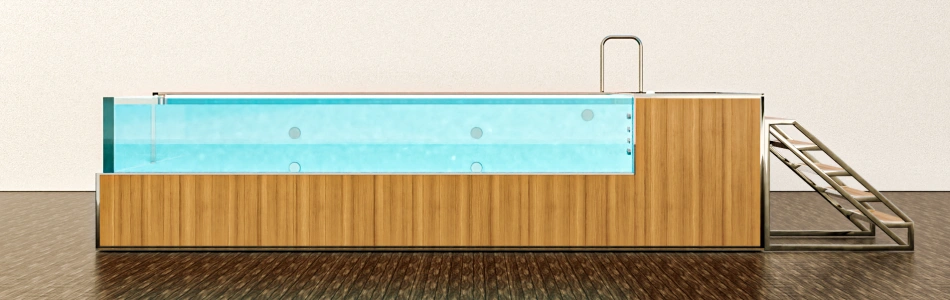

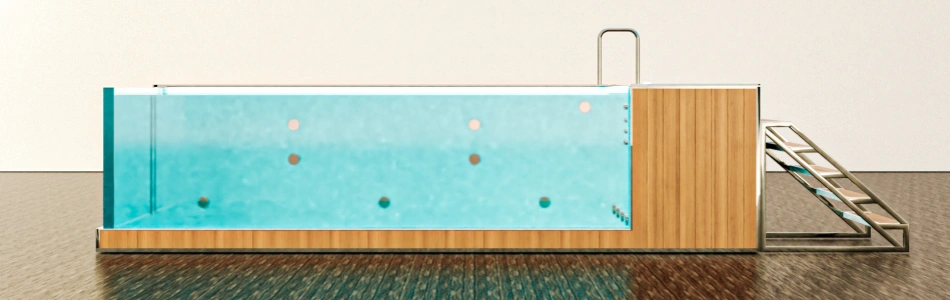

Metal pools are mostly made of steel or aluminum with a special coating to avoid rusting. The main types include:

- Galvanized Steel Pools – Coated with zinc to slow down rusting but still vulnerable in high-salt environments.

- Aluminum Pools – More resistant to corrosion than steel, but susceptible to pitting in saline conditions.

- Stainless Steel Pools – Highly durable and corrosion-resistant but significantly more expensive.

- Coated Metal Pools – Feature specialized coatings (e.g., powder coating or vinyl lining) for extra protection against moisture and chemicals.

Benefits of Metal Pools

Despite the challenges of coastal environments, many homeowners still opt for metal pools because of their unique advantages.

- Affordability – Metal pools are cheaper than concrete or fiberglass pools, and therefore, it will not be a big deal to install them.

- Strength and Durability – Compared to other types of pools, metal pools are very strong and are capable of withstanding pressure.

- Quick Installation – Concrete pools take weeks to plan and construct, while metal pools can be installed in a short period.

- Customization Options – Metal pools come in different sizes and styles, thus making them ideal for installation in different locations.

However, these benefits often come with a catch—higher maintenance requirements in salty environments.

Environmental Challenges in Coastal Areas

Any owner of a home near the coast is bound to experience some of these climatic factors that affect the durability of pools.

Effects of Salt-Laden Air on Metal

Salt is the biggest threat to metal pools, especially in the coastal regions. It is in the air, water, and even the ground, making it hard to escape. Several major problems arise from exposure to salt:

- Accelerated Corrosion – Salt hastens the rate of corrosion, which results in rust and the deterioration of the structure.

- High Humidity – Moist air accelerates the corrosion process, even if the pool is not in direct contact with seawater.

- Thermal Expansion and Contraction – Due to the fluctuating temperatures in coastal regions, the metal undergoes expansion and contraction, leading to cracking and other structural problems.

Comparing Coastal vs. Inland Pool Conditions

The durability of a metal pool depends on its location.

- Inland Pools – Since these pools are not exposed to salt water, they tend to have a longer lifespan. Metal pools in non-coastal areas can last over 20 years if properly maintained.

- Coastal Pools—If metal pools are built close to the coast, they will start to show signs of rusting in approximately 2-3 years, depending on the quality of the metal.

Even the best protective coatings can wear down faster in coastal environments, making regular maintenance essential.

Long-Term Performance: Real-World Reviews

Homeowners and pool professionals who have used metal pools in coastal areas report a mix of positive and negative experiences.

Performance After 5 Years

After five years, some signs of aging begin to show.

- Rust Formation – In the initial stage, rust tends to develop at regions such as the seams, bolts, and edges of the coated surface where the protective coating tends to corrode.

- Coating Deterioration – Coating on the metal surface may erode or fissure, leaving the metal susceptible to rusting.

- Higher Maintenance Needs – Cleaning, rust treatments, and part replacements become frequent.

- Structural Stability – It may warp or buckle slightly, especially during windy conditions or where it has been improperly installed.

Insights from 10+ Years of Use

After more than a decade, metal pools need a lot of maintenance or need to be replaced altogether.

- Severe Corrosion – Rust is not restricted to a surface level but spreads deeper into the material's structure. Stainless steel pools are more resistant to water effects, but they also experience oxidation.

- Frequent Part Replacements – Ladders, brackets, and bolts deteriorate due to rust and are replaced frequently.

- Weakened Structure – There could be buckling and uplifting of some panels, which may be dangerous.

- High Maintenance Costs – Repairs are expensive, and some homeowners opt to change to fiberglass or concrete.

Common Corrosion and Structural Issues

- Rust Accumulation in High-Stress Areas – Joints, screws, and bolts are the first parts to rust and this affects the strength of connections.

- Pitting in Aluminum Pools – Even though aluminum does not rust, it is a material that is susceptible to pitting, which reduces its strength over time.

- Failure of Protective Coatings – Coating also deteriorates over some period of time due to extreme weather, hence exposing the metal to serious corrosion.

- Buckling & Deformation – The panels are susceptible to heat and pressure and may buckle, thus posing a threat to the stability of the pool.

Maintenance Requirements Over Time

Maintenance is an essential factor that can ensure the lasting duration of a metal pool in a coastal region.

Routine Maintenance in Salty Environments

Here are some recommendations for homeowners to maintain the metal pool in the best state:

- To prevent the accumulation of salt, it is recommended to wash the pool with fresh water often.

- Coatings should be inspected and repaired regularly to avoid the formation of rust.

- Install sacrificial anodes like those on boats so that the pool railing absorbs the corrosion before it spreads to the railing.

- Ensure that water chemistry is well-balanced to avoid chemical reactions that enhance the corrosion process.

Cost and Effort of Upkeep

- Corroding ladders, bolts, and wall panels have to be replaced.

- Higher application of chemicals and inhibitors of corrosion.

Lack of maintenance can result in full replacement of the pool, which is much costlier in the long run.

Comparing Metal Pools with Other Materials

Metal vs. Fiberglass in Coastal Areas

- Fiberglass pools do not rust and are low on the maintenance scale.

- Metal pools are stronger than composite ones, but corrosion becomes a big issue.

- There are initial costs that are higher for fiberglass pools, but the frequency of repairs is relatively low.

Metal vs. Concrete Pools by the Sea

- Concrete pools last longer but require resurfacing every 10–15 years.

- Metal pools are cheaper initially, but maintenance costs add up over time.

- Concrete can develop cracks in shifting coastal soil, requiring patching.

Tips to Extend the Lifespan of Metal Pools

By employing the right measures, one can reduce the corrosion rate and further deterioration of the structures.

Protective Coatings and Treatments

A protective coating is one of the most efficient methods of preventing rust and corrosion in metal pools.

- Epoxy Coatings – This layer provides a hard and waterproof barrier to the metal, which enables it not to be exposed directly to water or salt.

- Powder Coating – This gives a long-lasting and anti-rust surface coat to the metal surface.

- Vinyl Liners – This is a protective covering that helps in shielding the structure from the water in the pool.

- Rust Inhibitors – Chemical treatments can slow the oxidation process, reducing rust buildup over time.

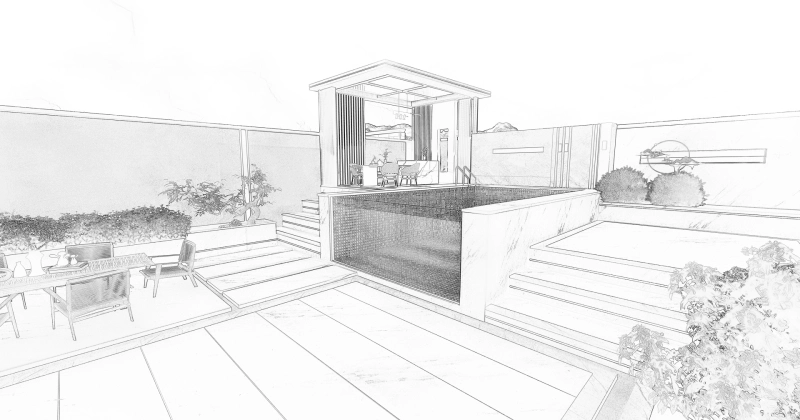

Strategic Pool Design and Placement

The location and type of design of a metal pool greatly influence its longevity.

- Wind Barriers – The use of fences, hedges, or walls reduces the amount of salt that is carried by the wind, hence reducing cases of corrosion.

- Elevated Installations – The pool can be constructed slightly above the ground level to minimize contact with damp soil and moist salt.

- Drainage Considerations – Drainage is an important factor to consider since water accumulation can promote rusting around the swimming pool.

Maintenance Best Practices

To avoid early wearing off, maintenance should be routinely conducted.

- Wash the metal surfaces with fresh water to remove salt deposits that accumulate.

- Early detection and treatment of small rust spots will prevent them from spreading.

- Coatings must be reapplied on an annual basis to maintain resistance to moisture and salt.

- Maintain a balanced pH to prevent corrosive reactions with metal components.

Expert Opinions and Industry Recommendations

Pool professionals emphasize the importance of material selection and consistent maintenance for metal pools in coastal areas.

What Pool Installers Say About Coastal Installs

- Stainless steel is the best metal option – While expensive, it offers the highest resistance to rust and corrosion.

- Aluminum performs better than galvanized steel – Although it can pit over time, it resists rust better.

- Regular maintenance is critical – Neglecting small rust spots or coating failures can lead to significant damage in just a few years.

New Materials and Technologies

Recent advancements offer improved durability for metal pools.

- Hybrid Pools – Combine metal frames with non-metallic panels to minimize corrosion risks.

- Self-Healing Coatings – These coatings repair minor surface damage, prolonging pool lifespan.

- Enhanced Sacrificial Anodes – Modern anodes absorb corrosion, protecting metal components more effectively.

Cost-Benefit Analysis

Before deciding on a metal pool for coastal homes, one has to consider the economic advantages and disadvantages.

Short-Term Savings vs Long-Term Costs

They are cheaper to install than fiberglass or concrete but have very high maintenance costs in coastal regions. Seawater makes them corrosive, so they need constant maintenance and repairs. Investing in high-quality coatings will pay off in the future because the maintenance costs will be lower.

Value for Coastal Homeowners

When using it for a short period, say five to ten years, then the metal pools are comparatively cheaper. However, for long-term use, some other materials, such as fiberglass or concrete, may be more appropriate in terms of low maintenance. However, if the homeowners are willing to take the responsibility of maintaining the pool, then metal pools are not a bad idea at all.

Conclusion

Metal pools in coastal regions are two-sided sods. They are cheap, durable, and easy to fix, but they need a lot of attention to avoid rusting. Owners who take the time to maintain their pools will be able to increase their life expectancy, but for those who do not want to spend much time on it, fiberglass or concrete are better choices in the long run.

So, if you plan to install a metal pool on the coast, be ready for additional efforts, or if you want it to look like new for many years, use protective equipment.