How Are Plexiglass Pools Built? Inside the Construction of See-Through Pools

These stunning-looking plexiglass pools have been featured everywhere on social media, from rooftops and resorts to backyard spaces. Some of us still can not believe how they can make glass pools that do not break.

The idea of being able to swim and glance through the wall is very interesting and a bit disorienting at the same time. You might have been wondering (or even doubting that it actually works) how those transparent swimming pools are made.

In this article, we will understand the layout and construction of plexiglass swimming pools, why they're so robust, and why they have become the most popular pool designs in 2025. If you are thinking about constructing a plexiglass pool in your backyard, this step-by-step guide can come in handy for you.

What Is Plexiglass?

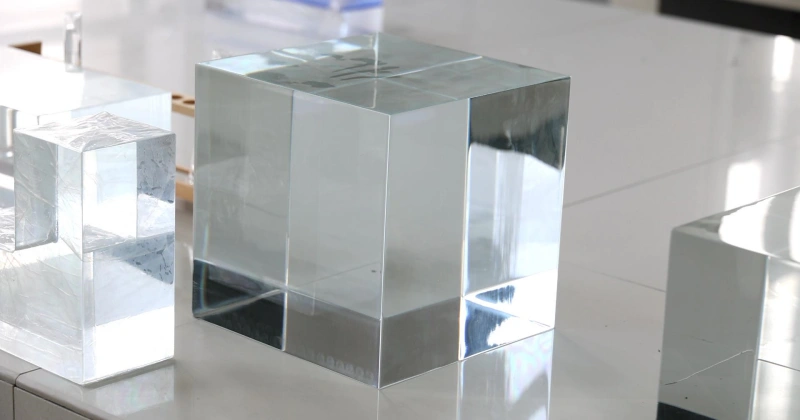

Plexiglass is not technically glass, but what is it? To put it simply, it is a polymer, a petroleum-based thermoplastic material (Acrylic) that has equal (sometimes even greater) transparency to glass.

Acrylic, which is the base ingredient of plexiglass, is formed as a result of the polymerization of methyl methacrylate (MMA). It was developed in 1933, and since this resembles glass so much with the glass, it is often known as Acrylic glass.

Due to its wide range of properties, acrylic is often used in a number of applications, like swimming pools, aquariums, bulletproof barriers, and airplane windows. The material is significantly lighter and more robust than glass, making it a viable option in applications where strength and transparency are required.

Acrylic, Acrylic glass, Poly methyl methacrylate (PMMA), and Plexiglass are different names for the same product, and they are often used interchangeably. So, whenever you hear any of these, you should know that the material is lighter than glass and is robust enough to stop a bullet.

Why is Plexiglass used for pool construction?

Among many notable uses of Plexiglass is its use in the pool walls, floors, and windows. But why Plexiglass? Why don’t we simply use glass?

Here’s why:

Durable

Acrylic sheets are extremely durable, especially compared to glass. They do not shatter, have equal (or better) transparency than glass, and have great impact resistance, making them an ideal choice for transparent pools.

Easy to work with

Don’t get carried away with their robustness; acrylic sheets are lighter (at least 50%) compared to glass sheets, making them much easier to work with. This lighter weight reduces the installation costs significantly, making acrylic pools a better choice compared to glass pools.

Exceptional transparency

Acrylic (PMMA) glass pools allow up to 92% of the light to pass through, while the glass pools can only transmit up to 88%. This greater transparency, coupled with its UV resistance, makes Plexiglass pools a great choice for high-end, exotic pools.

Customization options

You can create a Plexiglass pool in any design or shape due to the exceptional design flexibility of acrylic pools. They can be molded to form a variety of pool designs, from curved pools to infinity designs. With this much customization, you can create a pool to suit any indoor or outdoor setting.

From lightweight build to exceptional transparency, a Plexiglass pool has all the qualities you need in a transparent pool.

How are Plexiglass pools built?

Now that we know what Plexiglass is and why it is used for pool construction, it's time that we talk about how we can make Plexiglass pools from scratch. Although the exact construction process of Plexiglass pools depends on the available space, pool wall thickness, and other important factors, the process normally has three phases:

Design phase

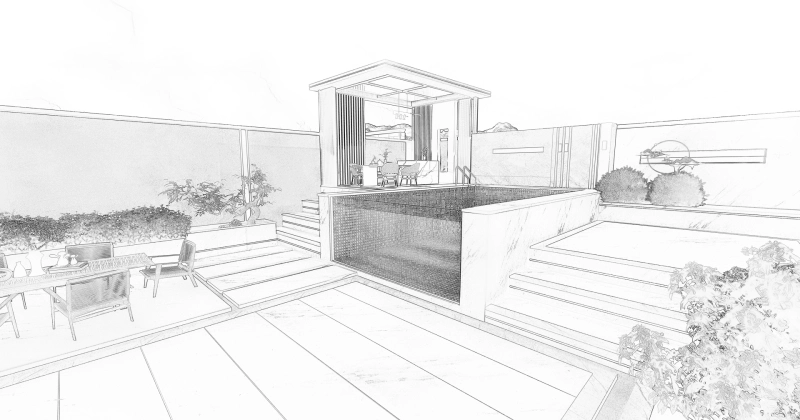

This is what you need to do right after you have decided to build a Plexiglass pool. It involves a site assessment to develop a preliminary design, the type of pool you would need, pool size, and depth. Based on these, the manufacturer will determine the size and thickness of PMMA panels to be used for the pool.

After the assessment is complete, the design team will make a concept design for your pool. This will help you visualize how the pool will look in your backyard. You can take your time to go through the design and decide if you want to make any changes to the pool layout.

Once you have given your feedback, the designer will refine the final design and forward it to the next process.

Construction phase

The construction phase depends on the type of installation you choose. You can either choose:

Completely in-ground pools

Above-ground pools

Partially in-ground pools

Rooftop pools

In completely in-ground pools, the acrylic panels are used as the extended pool walls or visible portions, and the floor is mostly made of non-shrinkable concrete.

In partially in-ground pools, acrylic parts are used in the walls, windows, and sometimes the floor of the pool. They offer a hybrid approach compared to in-ground and above-ground pools.

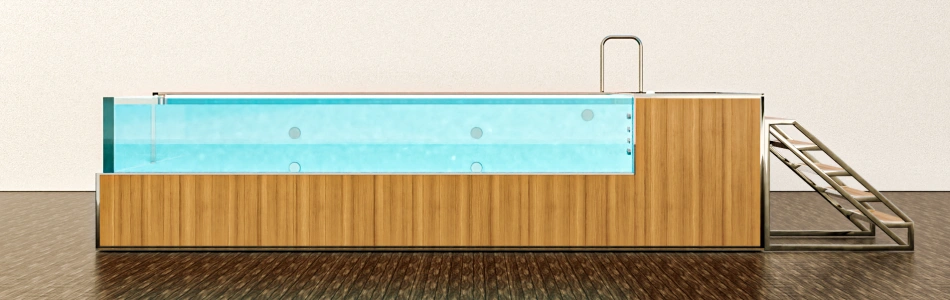

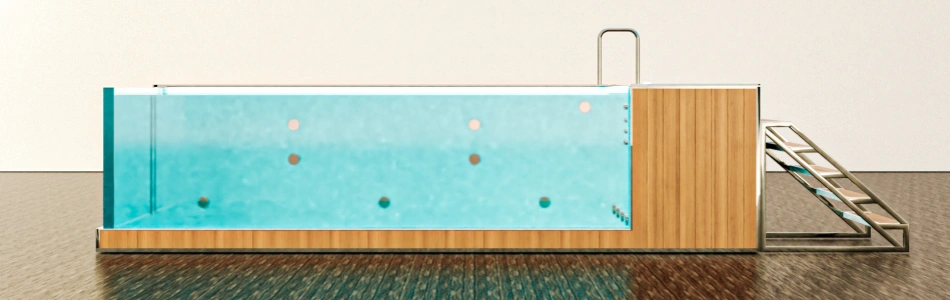

Above-ground pools are often completely made using acrylic panels, with plumbing and electrical fittings. They can be used both indoors and outdoors based on your requirements.

Rooftop pools are pretty similar to the above-ground pools; they are just a little smaller in size to accommodate the smaller space on most roofs.

The design and bonding mechanism greatly depend on the type of configuration you choose for your pool.

Installation phase

Once the construction and ground prep are completed, now time to install your Plexiglass swimming pool. For complete or partially in-ground pools, you need to prepare the ground through excavation or base preparation. Although above-ground and rooftop pools don’t need excavation or digging, you need sufficient ground prep to create a solid base.

After the pool is installed and plumbing and electrical connections are secured, the next step is to fill the pool. This step ensures that there is no leakage or any other issues. The installation team will also test the water quality and ensure that all systems are working properly.

The final step is to complete the landscaping. You can add poolside furniture, patios, and plants to enhance the overall aesthetics of your poolside area. You can also add a temperature control system to make your pool functional throughout the year and a water treatment system to make the pool water fresh at all times.

DIY or Professional Installation?

Now, you may be asking yourself: Do I choose professional installation or do it myself?

Plexiglass pools are a very specialized type and require expertise in structural glazing, handling of the material, and chemical bonding. One misstep in aligning or sealing can ruin the whole pool and result in possible leaks or stress cracks over time. Acrylic is not concrete, tile, or any other DIY material, so it needs special handling throughout the installation.

To ensure long-term safety and performance, it’s vital to hire professional installers with experience in:

Pool hydraulics and balanced water flow

Acrylic chemistry and sealant compatibility

Load-bearing calculations for transparent panels

Thermal movement management in extreme climates

You can also check out our installation guide to make the most of your Plexiglass pool installation.

Important considerations before installation

Although the installation process is pretty seamless with professional installers, you still need to make sure you follow these important considerations.

Handling water pressure at depth

Make sure your plexiglass pool can handle the water pressure at a certain depth. The deeper the pool, the greater the pressure on the pool wall. Acrylic panels are normally strong, but choosing the wrong thickness or using the wrong adhesive can compromise the overall structural integrity.

Coping with temperature fluctuations

Acrylic reacts more to temperature changes compared to glass. Make sure pool installers use proper gaps, flexible seals, or expansion joints to avoid cracks or structural issues as the temperature shifts between day and night or across seasons.

UV resistance and outdoor durability

Remember, not all acrylics are equally UV stable, so verify that the material is rated for long-term outdoor use. In outdoor pools, ensure the Plexiglass used is UV-resistant to prevent yellowing and brittleness from prolonged sun exposure.

If you are looking for a reliable acrylic pool, then you must consider the R-series from Aupool. With just 72 hours of installation time, this is your chance to bring your dream pool to your home.

Final Thoughts

The plexiglass pools are not just a fashion anymore; they are a mixture of science, safety, and style. From robustness to the glass-like transparency, they offer a perfect combination of properties for your see-through swimming pool.

While the installation process may seem a breeze, always trust professional and licensed installers with the right knowledge of materials, load analysis, and chemical bonding. When you leave the heavy-lifting to professionals, your structure will not only be beautiful but also strong enough to last many years in the future.